JMD8H4 Magnet speaker parts

Basic Info

Model No.: JMD8H4

Product Description

Specifications magnet speaker parts

more then 400 types available

small order accept

more size can be made

fast delivery time

JMD8H4 Magnet speaker parts What is Neodymium Magnet? A neodymium magnet (also known as NdFeB, NIB, or Neo Magnet), the most widely used type of rare-earth magnet, is a Permanent Magnet made from an alloy of neodymium, iron, and boron to form the Nd2Fe14B tetragonal crystalline structure.Developed in 1982 by General Motors and Sumitomo Special Metals, Neodymium Magnets are the strongest type of permanent magnet made.They have replaced other types of magnet in the many applications in modern products that require strong permanent magnets, such as motors in cordless tools, hard disk drives, and magnetic fasteners. Supplier of the world`s strongest magnets. Product information:

Product information:

More introduction:

nickel coated magnet speaker parts

More choice for you,different neodymium magnet

More choice for you,different neodymium magnet

For small package,we recommend magnetised-shield package for express delivery or by air. For large package,we recommend wooded package by sea

For small package,we recommend magnetised-shield package for express delivery or by air. For large package,we recommend wooded package by sea  Applications of magnet speaker parts

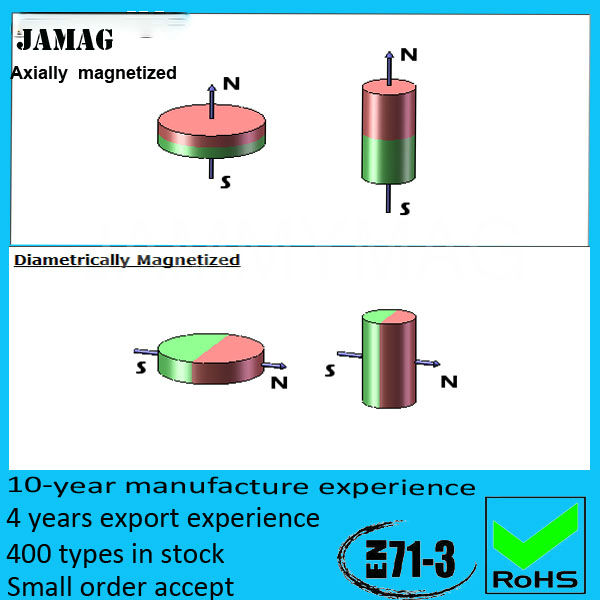

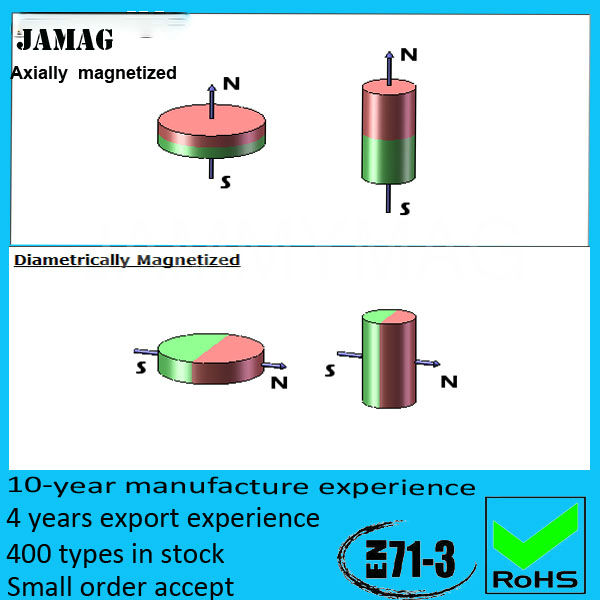

Applications of magnet speaker parts  Magnetised direction DISC neodymium magnets can be axially or drametrically magnetized.

Magnetised direction DISC neodymium magnets can be axially or drametrically magnetized.  Trade terms:

Trade terms:

History and manufacturing techniques In 1982, General Motors (GM) and Sumitomo Special Metals discovered the Nd2Fe14B compound. The effort was principally driven by the high material cost of the SmCo permanent magnets, which had been developed earlier. GM focused on the development of melt-spun nanocrystalline Nd2Fe14B magnets, while Sumitomo developed full-density sintered Nd2Fe14B magnets. GM commercialized its inventions of isotropic Neo powder, bonded Neo magnets, and the related production processes by founding Magnequench in 1986. Magnequench, now part of the Neo Materials Technology, Inc., supplies melt-spun Nd2Fe14B powder to bonded magnet manufacturers. The Sumitomo facility has become part of the Hitachi Corporation and currently manufactures and licenses other companies to produce sintered Nd2Fe14B magnets. Hitachi holds more than 600 patents covering Neodymium magnets. Sintered Nd2Fe14B tends to be vulnerable to corrosion. In particular, corrosion along grain boundaries may cause deterioration of a Sintered Magnet. This problem is addressed in many commercial products by adding a protective coating. Nickel plating or two-layered copper-nickel plating are the standard methods, although plating with other metals or polymer and lacquer protective coatings is also in use.

About us:

About us:

Why choose Jamag: 1.We work with our greatest passion 2.We have 10 years manufacture experience and 4-year exporting experience 3.We insure that you will satisfied with our service 4.We can offer you more advice and professional information of magnets,no matter you place an order or not. 5. wanna be friends with our customers. 6.We have 600 types magnets available now,small order accept Dear Friend, Thanks so much for your time to look through this page. No matter you purchase magnet from us or not,we will be glad to offer you professional advice. If there is anything we can do for you,pls feel free to let me know! Contact me ,i`ll be there!

Why choose Jamag: 1.We work with our greatest passion 2.We have 10 years manufacture experience and 4-year exporting experience 3.We insure that you will satisfied with our service 4.We can offer you more advice and professional information of magnets,no matter you place an order or not. 5. wanna be friends with our customers. 6.We have 600 types magnets available now,small order accept Dear Friend, Thanks so much for your time to look through this page. No matter you purchase magnet from us or not,we will be glad to offer you professional advice. If there is anything we can do for you,pls feel free to let me know! Contact me ,i`ll be there!  Last Update Time:2013-11-13 Contact us if you need more details on Magnet Speaker Parts. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mini Speaker Parts、Speaker Parts Magnet. If these products fail to match your need, please contact us and we would like to provide relevant information.

Last Update Time:2013-11-13 Contact us if you need more details on Magnet Speaker Parts. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mini Speaker Parts、Speaker Parts Magnet. If these products fail to match your need, please contact us and we would like to provide relevant information.

more then 400 types available

small order accept

more size can be made

fast delivery time

JMD8H4 Magnet speaker parts What is Neodymium Magnet? A neodymium magnet (also known as NdFeB, NIB, or Neo Magnet), the most widely used type of rare-earth magnet, is a Permanent Magnet made from an alloy of neodymium, iron, and boron to form the Nd2Fe14B tetragonal crystalline structure.Developed in 1982 by General Motors and Sumitomo Special Metals, Neodymium Magnets are the strongest type of permanent magnet made.They have replaced other types of magnet in the many applications in modern products that require strong permanent magnets, such as motors in cordless tools, hard disk drives, and magnetic fasteners. Supplier of the world`s strongest magnets.

Product information:

Product information: | Name | JMD8H4 Magnet speaker parts | Coating | nickel |

| Item NO. | JMD8H4 | Net weight | 1.49g per piece |

| Material | Neodymium magnet | Pull force | 1.48lb=0.67kg |

| Shape | Round | Working temperature | ≤80°C |

| Size | D20*2mm(diameter*thickness) | Magnetism direction | Through thickness |

| Grade | N35 | In stock | Yes |

| Other sizes available | D8*2.5mm,D8*5mm,D8*3mm more size available | ||

| Items | Neodymium magnet raw material | |

| Material | neodymium-iron-boron | |

| Shape available | Disc,Cylinder,Block,Ring,Countersunk,Segment,Trapezoid,Irregular shapes and more;More shapes can be customized. | |

| Coating/Plating | Ni-Cu-Ni,Nickel,Zinc,Gold,Silver,Epoxy and more. | |

| Working Temperature | Grade | Temp.Coefficient |

| N35-N52 | 80°C (176°F) | |

| N35M-N45M | 100°C (212°F) | |

| N33H-N42H | 120°C (248°F) | |

| N30SH-N40SH | 150°C (302°F) | |

| N28UH-N35UH | 180°C (356°F) | |

| N28EH-N38EH | 180°C (356°F) | |

| N30AH-N33AH | 220°C (428°F) | |

| Technology | We have advanced R&D center,quality control and professional machining technicians. | |

| Application | Neodymium magnet raw magnetrials are widely used in industrial field,such as speaker,louder speaker,sensor,motor,alternator ect;And also it is popular in ladies bags,purses,shoes,crafts and jewelry ect. | |

More choice for you,different neodymium magnet

More choice for you,different neodymium magnet

For small package,we recommend magnetised-shield package for express delivery or by air. For large package,we recommend wooded package by sea

For small package,we recommend magnetised-shield package for express delivery or by air. For large package,we recommend wooded package by sea  Applications of magnet speaker parts

Applications of magnet speaker parts  Magnetised direction DISC neodymium magnets can be axially or drametrically magnetized.

Magnetised direction DISC neodymium magnets can be axially or drametrically magnetized.  Trade terms:

Trade terms: | Trade terms | FOB Ningbo |

| Payment | T/T,paypal,west union,Aliexpress |

| Lead time | for small quantity 5-7 days;for large quantity 7-15 days |

| Samples policy | samples free for few,but customer needs to pay the express fee |

| Transportation | by air,by sea,by express |

| MOQ | 100pcs |

About us:

About us: | Company Name | Xiamen Jammymag Electronic S&T Co., Ltd. |

| Brand Name | Jamag |

| Business Type | Manufacturer, Trading Company |

| Main Products | Magnet,Neodymium Magnet,Ndfeb Magnet,Permanent Magnet,Strong Magnet,Neocub,Magnet botton |

| Operational Address | Hengdian industruy zone, Dongyang City,ZheJiang province |

| Number of Employees | 11 - 50 People |

| Number of R&D Staff | Less than 5 People |

| Number of QC Staff | Less than 5 People |

| Main Markets | North America,Eastern Europe,Mid East, Eastern Asia |

| Contract Manufacturing | OEM Service Offered |

Why choose Jamag: 1.We work with our greatest passion 2.We have 10 years manufacture experience and 4-year exporting experience 3.We insure that you will satisfied with our service 4.We can offer you more advice and professional information of magnets,no matter you place an order or not. 5. wanna be friends with our customers. 6.We have 600 types magnets available now,small order accept Dear Friend, Thanks so much for your time to look through this page. No matter you purchase magnet from us or not,we will be glad to offer you professional advice. If there is anything we can do for you,pls feel free to let me know! Contact me ,i`ll be there!

Why choose Jamag: 1.We work with our greatest passion 2.We have 10 years manufacture experience and 4-year exporting experience 3.We insure that you will satisfied with our service 4.We can offer you more advice and professional information of magnets,no matter you place an order or not. 5. wanna be friends with our customers. 6.We have 600 types magnets available now,small order accept Dear Friend, Thanks so much for your time to look through this page. No matter you purchase magnet from us or not,we will be glad to offer you professional advice. If there is anything we can do for you,pls feel free to let me know! Contact me ,i`ll be there!  Last Update Time:2013-11-13 Contact us if you need more details on Magnet Speaker Parts. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mini Speaker Parts、Speaker Parts Magnet. If these products fail to match your need, please contact us and we would like to provide relevant information.

Last Update Time:2013-11-13 Contact us if you need more details on Magnet Speaker Parts. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mini Speaker Parts、Speaker Parts Magnet. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Magnet Sort by Size > Other Magnet

Other Products

Hot Products

neodymium 1/8 x 1/8 barpocket magnet buttonhot sale titanium magnetic rubber bracelets for salehigh quality small thin round magnet for salehot sale 3m adhesive disc neodymium magnet for salehigh quality 17mm magnet hidden snap buttons for saleHot popular cabinet magnetic hook for saleChinese self adhesive rubber magnet sheet,rubber magnet rollFactory supply high quality proper price making permanent magnetNeodymium Magnet Composite and disc Shape Invisible Sew In MagnetButton Type and Metal Material magnet snap buttonCompetitive price ferrite ring from China producerHigh quality musical fridge magnets for factory supplyHigh quality magnet sphere mold for factory supplyrare earth neodymium magnet balls 216 5mmHigh quality purchase neodymium magnets for factory supply